HRE Series Dual Tower Heat Regenerative Desiccant

Air Dryers

100 to 6000 SCFM

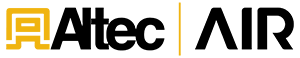

Altec AIR’s HRE Series Heat Regenerative Desiccant Air Dryers apply a regulated amount of dried process air, which has been heated by way of a low watt density heater, down through the desiccant bed (counter current). This heated purge air is then exhausted to atmosphere, removing the water vapor that had adhered to the desiccant during the previous cycle.

- ASME / CRN Approved Pressure Vessels

- Factory installed Filters w/ Differential Pressure Gauges and Pre-Filter Timer Drain

- Feature Rich ETL Listed Pro-Logic Controller w/ NEMA 4X Enclosure

- Regulated Purge Flow for Optimum Setting, Regardless of Operating Pressure

- ISO 8573.1 Class 2 -40°F/C Standard Outlet Dewpoint

| Standard Features: |

|---|

|

| Optional Features: | |

|---|---|

|

|

| General Specifications: | |||||||

|---|---|---|---|---|---|---|---|

| INLET Flow: (SCFM @ 100 PSIG) |

Inlet / Outlet Ports (NPT) |

Power Requirement |

Heater (KW) |

Approx. Purge (SCFM @ 100 PSIG) |

|||

| HRE-0100-1 | 100 | 1" | 120 VAC, 1 Ph, 60 Hz |

1.5 | 8 | ||

| HRE-0130-1 | 130 | 10 | |||||

| HRE-0200-2 | 200 | 1-1/2" | 230 VAC, 1 Ph, 60 Hz |

3.0 | 15 | ||

| HRE-0250-4 | 250 | 460 VAC, 3 Ph, 60 Hz |

19 | ||||

| HRE-0300-4 | 300 | 23 | |||||

| HRE-0400-4 | 400 | 2" | 5.0 | 30 | |||

| HRE-0550-4 | 550 | 6.0 | 41 | ||||

| HRE-0650-4 | 650 | 7.5 | 49 | ||||

| HRE-0800-4 | 800 | 9.0 | 60 | ||||

| HRE-1000-4 | 1000 | 3" (FLG) | 12.0 | 75 | |||

| HRE-1250-4 | 1250 | 94 | |||||

| HRE-1500-4 | 1500 | 4" (FLG) | 18.0 | 113 | |||

| HRE-2000-4 | 2000 | 25.0 | 150 | ||||

| HRE-2500-4 | 2500 | 185 | |||||

| HRE-3000-4 | 3000 | 30.0 | 225 | ||||

| HRE-4000-4* | 4000 | 6" (FLG) | 38.0 | 300 | |||

| HRE-5000-4* | 5000 | 50.0 | 375 | ||||

| HRE-6000-4* | 6000 | 60.0 | 450 | ||||

Sizing based on the Compressed Air and Gas Institute CAGI ADF 200 Standard for Compressed Air of 100 PSIG inlet pressure, 100°F inlet temperature and -40°F pressure dew point providing ISO Quality to standard 8573-1 rating 1-2-1 for Compressed Air Quality.

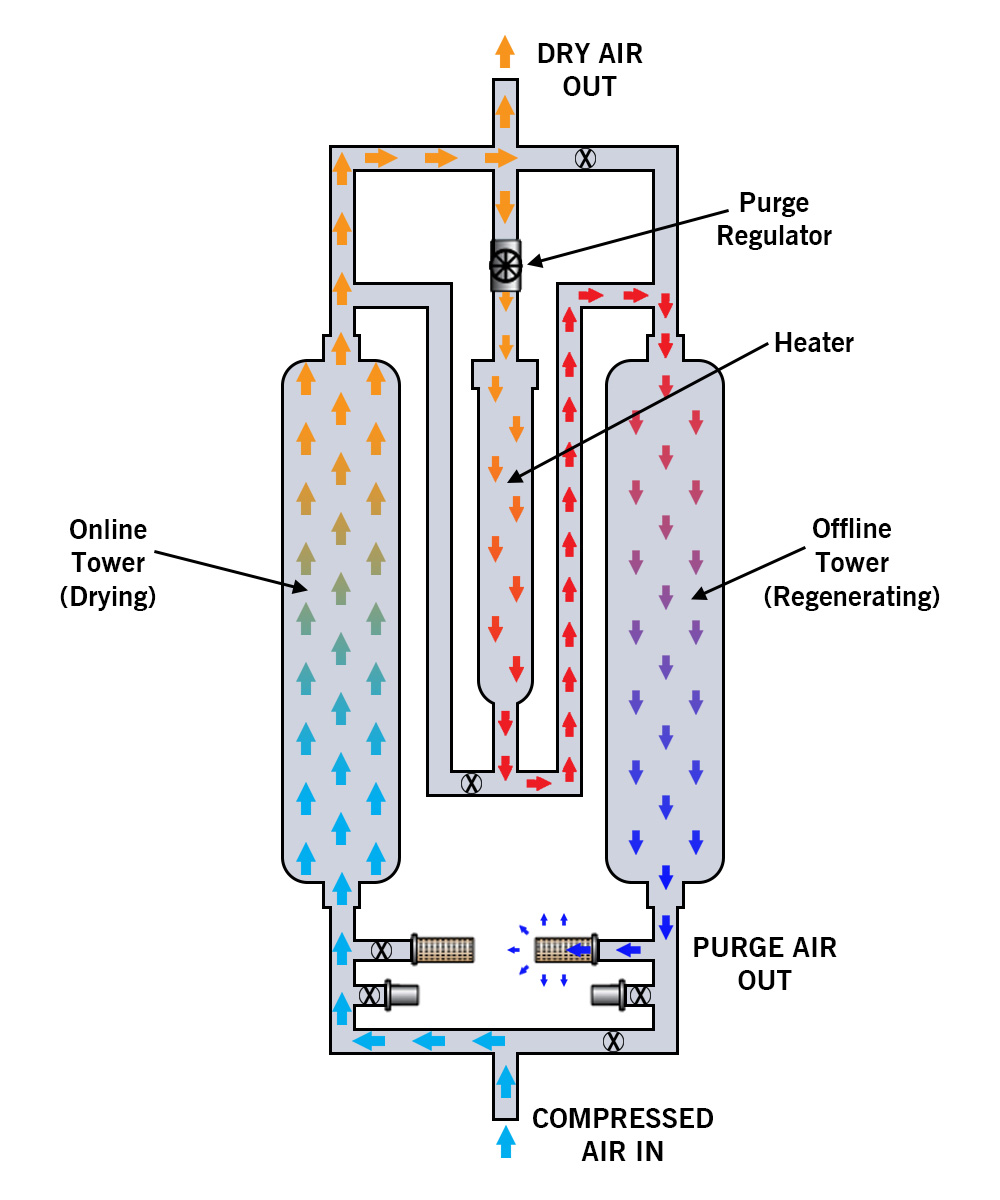

| Dimensions: | ||||

|---|---|---|---|---|

| Width (in) |

Depth (in) |

Height (in) |

Weight (lbs) |

|

| HRE-0100-1 | 27 | 30 | 79 | 550 |

| HRE-0130-1 | 32 | 630 | ||

| HRE-0200-2 | 31 | 36 | 90 | 940 |

| HRE-0250-2 | 38 | 91 | 1,018 | |

| HRE-0300-4 | 1,095 | |||

| HRE-0400-4 | 32 | 40 | 94 | 1,390 |

| HRE-0550-4 | 44 | 49 | 93 | 1,700 |

| HRE-0650-4 | 52 | 1,855 | ||

| HRE-0800-4 | 98 | 2,270 | ||

| HRE-1000-4 | 52 | 48 | 102 | 2,900 |

| HRE-1250-4 | 96 | 70 | 101 | 4,180 |

| HRE-1500-4 | 4,530 | |||

| HRE-2000-4 | 84 | 121 | 6,210 | |

| HRE-2500-4 | 127 | 6,795 | ||

| HRE-3000-4 | 90 | 92 | 112 | 7,620 |

| HRE-4000-4* | 117 | 127 | 9,565 | |

| HRE-5000-4* | 133 | 116 | 105 | 11,055 |

| HRE-6000-4* | 145 | 123 | 104 | 14,125 |

* Units 4000 SCFM and larger with factory packaged filters are provided on two bases designed to bolt together at installation.

| Multiplier Table (Sizing Dryers for Variable Conditions): | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

Maximum Inlet Flow = INLET Flow (above) x INLET Pressure Correction Factor (A) x INLET Temp Correction Factor (B) |

||||||||||

| Actual Pressure (PSIG) | 60 | 70 | 80 | 90 | 100 | 110 | 120 | 130 | 140 | 150 |

| Correction Factor (A) | 0.66 | 0.72 | 0.82 | 0.90 | 1.00 | 1.07 | 1.15 | 1.24 | 1.33 | 1.40 |

| Inlet Temp (°F) | 80 | 90 | 100 | 110 | 120 |

| Correction Factor (B) | 1.40 | 1.32 | 1.00 | 0.75 | 0.58 |

HRE Series Drying Process

Compressed air, saturated with water vapor, flows upward through the Online (Drying) Tower. The water molecules adhere to the porous surface of the Desiccant, where the residual water content of the compressed air is lowered to a Pressure Dew Point (PDP) of -40°F or lower. A regulated amount (7%) of dried process air is then heated by way of a low watt density heater and passed down through the Desiccant bed of the Offline Tower. This heated purge air, exhausted to atmosphere, removes the water vapor that adhered to the Desiccant during the previous cycle.

This tool will help you size the perfect HRE Series Desiccant Air Dryer for your Compressor Output and Environmental Conditions. Simply enter the data & conditions and you'll be presented with the Part Number for the HRE Series Air Dryer that will work optimally for those conditions. We will also provide Part Numbers for the Filter Kits that were created to match that HRE Series Air Dryer perfectly.

Please use the latest version of Chrome, Firefox or Safari.

Internet Explorer not currently supported.

Please use the latest version of Chrome, Firefox or Safari.

Internet Explorer not currently supported.

Need A Custom Sized Air Dryer?

Contact Altec AIR for assistance selecting the right dryer for your application.

All you need is the required Inlet or Outlet Flow Rate, Operating Pressure, and the required Dew Point.