For many installations of industrial air dryers, a dilemma can occur when trying to achieve the correct balance between desired specifications and efficiency in the applications. Sometimes there is no way around a requirement to achieve ultra-dry dew points, but are we always considering the point-of-use needs when implementing a dry air solution? Often the dry air system is configured with one end goal in mind which is dry air but doing so without accounting for the point-of-use factors that can lead to added expenses and wasted energy.

Two of the most common applications or requirements for ultra-dry dew points are environmental conditions (compressed air lines operating at or below freezing temperatures) or moisture-sensitive applications (electrical testing, laboratory processes, etc.). In these scenarios utilizing desiccant air dryers are necessary to provide these extreme requirements consistently, but are they always sized, specified, and installed efficiently? To get to our destination we must first know where to start and that all begins with understanding the facility and application requirements.

We know from experience that the more effort we put into the front end of a process the better the result will be. Therefore, we must ask the right questions to provide an efficient and viable solution. Here we discuss how point-of-use dryers can often save energy in applications that involve ultra-dry dew points.

Understanding the Requirement for Ultra Dry Dew Points

Before we can begin, we need to understand what is dew point? The dew point temperature is a measurement of the amount of moisture or water vapor in the air. The specific temperature is the temperature at which water will condense from the compressed air to a liquid. Any moisture in a compressed air system can be detrimental to the performance and life of the equipment utilizing the air.

To eliminate or minimize the amount of moisture in the system, compressed air dryers help to reduce the dew point of the air lines. The international standard ISO 8573-1 can guide these requirements. This standard identifies three primary contaminant types that are present in a compressed air system: particulates, water, and oil. Each is categorized and assigned a quality class where the end user can identify their requirements for their application or process.

There are several types of air dryers that produce different dew points to help meet the quality class of the water contaminant component outlined in ISO 8573-1. Refrigerated air dryers are the most common and can produce dew points of 38°F (3°C) Class 4 moisture content. The next most common are desiccant air dryers, which can achieve very low dew points from -40°F (-40°C) to -100°F (-73°C) Class 2 and 1 moisture content, respectively. These are the air dryers needed for operating at or below freezing ambient temperatures, as well as when using compressed air for moisture sensitive testing and processes.

To begin to determine the requirement for moisture content, the main two questions that need to be asked are, “What is the dew point required for each application in my system and what is the lowest operating temperature inside my compressed air system?”

Based on these questions, we can determine what type of dryer(s) need to be installed and if there is a solution to minimize the amount of airflow for Class 1 or 2 moisture content.

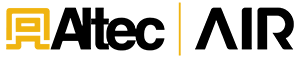

Heatless Regenerative Desiccant Air Dryer

There are several types of regenerative desiccant air dryers: heatless, heated (internally or externally), blower purge, and heat of compression. We are going to focus on the most popular and common type: Heatless regenerative desiccant air dryers. These air dryers use a process called Pressure Swing Adsorption to consistently provide clean dry air. These are one of the simplest forms of regenerative desiccant air dryers and are an economical option but do have a hidden cost.

Heatless desiccant air dryers come in a variety of sizes. From the larger units that can handle flow rates greater than 3,000 scfm and all the way down to the ultra-compact flow rates of 0.4 scfm. No matter the size, they all operate on the same principles.

These air dryers typically consist of a twin-tower construction. The towers are filled with desiccant which comes in a variety of sizes, shapes, and compositions. Desiccants are adsorbent materials that remove moisture from the compressed air stream down to extremely low-pressure dew points.

While one tower actively dries the compressed air stream, the other off-line tower is being regenerated. The regeneration process is initiated through a timed purge cycle that depressurizes the off-line tower and then bleeds a small portion of the ultra-dry outlet air from the on-line tower to the off-line tower through a flow control device. This air flow is the regeneration process is called the “purge air” and is typically 15 to 25 percent of the inlet air flow into the heatless air dryer.

The purge air used to regenerate the off-line desiccant tower is energy consumed to achieve the ultra-dry dew points. This energy loss can add up over time. There are however a few ways to help minimize the energy impact. Purge air economizers or dew point controllers are some of the more popular options and accessories that are available on these systems. These accessories monitor the outlet dew point and turn on or off the purge flow to be able to reduce the energy lost.

The larger systems are installed to match the inlet flow rate and conditions of the plant compressed air system. When selecting a desiccant air dryer it is imperative to understand the impact on both the air compressor and the plant air systems. Manufacturers create heatless desiccant dryer flow capacities to achieve -40°F (-40°C) pressure dew points based on Compressed Air and Gas Institute (CAGI) Standard ADF200 where dryer operating conditions are 100 psig, 100°F inlet air temperature, and 100% inlet air relative humidity.

.jpg)

Shown is a typical Installation of a large heatless desiccant air dryer, including a 0.1 micron coalescing pre-filter and one micron particulate after-filter.

Point-Of-Use Dryers

What is a point-of-use desiccant air dryer? These are smaller, more compact air dryers that are installed at an application that might require a lower dew point than the rest of the compressed air system.

These compact regenerative point-of-use desiccant air dryers have similar features to the larger (more traditional) models but are sized for smaller flow rates, which will use less purge to regenerate and will help reduce energy loss when looking at the entire compressed air system. Some other features include spring-loaded desiccant chambers which help immobilize the desiccant bed to extend the life of the desiccant and allow for multiple mounting configurations. Another difference is the purge functionality. The timing cycle on these smaller dryers ranges from one to three minutes whereas the larger dryers have a 10-minute cycle. Another distinguishing feature is the fixed-purge orifice integrated into the outlet shuttle valve assembly. The fixed orifice allows for out-of-the-box performance with minimal setup time at the installation.

A point-of-use dryer will be installed at the site of the application and will be sized for the outlet flow rate (or the demand of the application). Three key pieces of information required for sizing a point-of-use dryer are: required dew point, inlet pressure, and either inlet or outlet flow rate. With these smaller dryers, there is also the option to customize and dial-in the purge rate to minimize the wasted energy.

.jpg)

Shown is a typical installation of point-of-use heatless desiccant dryers with a 0.1 micron coalescing pre-filter and one micron particulate after-filter.

What follows are two different cases where a facility had the choice to install a larger desiccant air dryer, or a smaller point-of-use air dryer to meet their ultra-dry dew point requirements.

Cyclic Corrosion Test Chamber Application

A manufacturer in St. Joseph, Missouri, is adding a cyclic corrosion test chamber to their design assurance facility, which has an existing compressed air system. The air compressor is a 30 horsepower (hp) rotary screw machine with a refrigerated air dryer producing 38°F (3.333°C) pressure dew point at 125 psig. In accordance with the manual, the chamber requires 10 scfm of clean dry air at -40°F (-40°C) dew point and 100 to 110 psig.

The new chamber will run sporadically as required testing at the facility. Tests could run 24 hours/day, seven days a week for an extended period of time depending on the test procedure. There could also be periods of time when no test will be running. The facility had plenty of capacity to add 10 scfm to their demand for the new equipment.

The plant had a couple of options. One was to replace the refrigerated air dryer with a large desiccant air dryer to match the flow of the air compressor (160 scfm). Another option was to add a point-of-use heatless air dryer and install it at the application.

- Option 1 – large desiccant dryer: Inlet flow rate of 160 scfm, purge rate at 120 psi = 25.4 scfm when regenerating.

- Option 2 – point-of-use dryer with custom-sized purge orifice: Outlet flow rate 10 scfm, purge at 120 psi = 3.5 scfm when regenerating.

By utilizing a smaller point-of-use desiccant air dryer in Option 2 we can reduce the purge rate by 86% during regeneration, which can add up to a real energy savings as well as reduced capital expenses on the initial installation.

Variable Production Loads Application

A biotechnology manufacturing company located in Raleigh, North Carolina, developed a new product and process that requires large amounts of clean dry air in batches.

The process requires 18 scfm at -40°F (-40°C) pressure dew point per batch. They manufacture this product in many different locations around the world and have different schedules and production levels of this product up to 20 batches at a single time.

Each facility already has a compressed air system with a refrigerated air dryer and enough capacity to cover the demand of the new process. They considered options to size a desiccant air dryer to match the largest capacity of each facility or to purchase smaller desiccant air dryers sized per batch of product. These batches run 24 hours for five days at a time and start at different times.

In their Brazil facility, they had a maximum capacity for 20 batches running at a single time but averaged eight batches running at a single time during more than eight months of the year. If all 20 batches were running simultaneously, the facility would require a maximum outlet flow of 360 scfm.

- Option 1 – large desiccant dryer at 100 psi: inlet flow rate of 436 scfm, purge rate at 100 psi = 76 scfm when regenerating.

- Option 2 - point-of-use dryer with a standard purge orifice for each batch at 100 psi: inlet flow rate of 23.4 scfm, purge rate at 100 psi = 5.4 scfm when regenerating.

The plant could decrease the purge from 76 scfm to 43.2 scfm for a 43% reduction in purge consumption by using point-of-use dryer with Option 2 when the need is to only process eight batches. The larger desiccant dryer in Option 1 would, however, be more energy efficient when running at full capacity.

Selecting the Right Dryer Equals Energy Savings

There is no one-size-fits-all solution with compressed air treatment applications. To provide the best solution for any facility, we need to understand the specific dew point requirements for the facility’s environment, as well as each application. This can help us be more efficient and minimize the energy impact of ultra-dry dew point requirements to by selecting the right air dryer for the right application.

About the Author

Jim DiMaiolo is the Market Manager at Altec AIR. He has held various engineering and market development roles with Altec for nine years. Jim has a Bachelor of Science Degree in Mechanical Engineering from Duke University and is a licensed professional engineer in the State of Colorado. Contact Jim at tel: 908-902-1576, email: jim.dimaiolo@AltecAIR.com.

About Altec AIR

Since 1954, Altec AIR has been designing and manufacturing air-drying solutions in the United States for a variety of markets and applications. Whether your requirements are for desiccant or refrigerated air dryers, please visit www.AltecAIR.com.

All photos courtesy of Altec AIR.