RAD Series

Non-Cycling Refrigerated Air Dryers

25 to 2000 SCFM

Altec AIR’s RAD Series Non-Cycling Refrigerated Air Dryers are designed to meet the demand of your compressed air system with quality components that are built to last.

- Consistent & Reliable Dry Air - ISO Class 4 - 5

- Compact All-Aluminum Heat Exchanger Modules with Low Pressure Drops

- Programmable Automatic Electronic Drains

- Easy-Access Cabinet Design for Ease of Maintenance & Serviceability

- Suction & Discharge Pressure Gauges Provide Simple & Reliable Monitoring of the Dryer’s Refrigeration System

- Top Mounted Inlet & Outlet Connections Allow for Easy Installation of Dryer, Filters, & Bypass Valves

- ETL Listed Configurations (Pending)

| Standard Features: |

|---|

*NOTE: Voltage options are dependent on specific models. |

| Optional Features: | |

|---|---|

|

|

| General Specifications: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| RAD-0025A | RAD-0040A | RAD-0055A | RAD-0075A | RAD-0100A | RAD-0150A | ||||

| INLET Flow: (SCFM @ 100 PSIG) |

25 | 40 | 55 | 75 | 100 | 150 | |||

| Inlet / Outlet Ports (NPT) |

1/2" | 1" | 1-1/2" | ||||||

| Refrigerant Type | R134a | ||||||||

| RAD-0200A | RAD-0250A | RAD-0300A | RAD-0400A | RAD-0500A | RAD-0600A | |

| INLET Flow: (SCFM @ 100 PSIG) |

200 | 250 | 300 | 400 | 500 | 600 |

| Inlet / Outlet Ports (NPT) |

1-1/2" | 2" | 2-1/2" | |||

| Refrigerant Type | R134a | R404a | R449a | |||

| RAD-0750A | RAD-1000A | RAD-1250A | RAD-1500A | RAD-2000A | |

| INLET Flow: (SCFM @ 100 PSIG) |

750 | 1000 | 1250 | 1500 | 2000 |

| Inlet / Outlet Ports (NPT) |

3" | 4" | |||

| Refrigerant Type | R449a | R404a | |||

** Sizing based on Inlet Temperature of 100°F, Inlet Dew Point of 100°F, Inlet Pressure of 100 PSIG

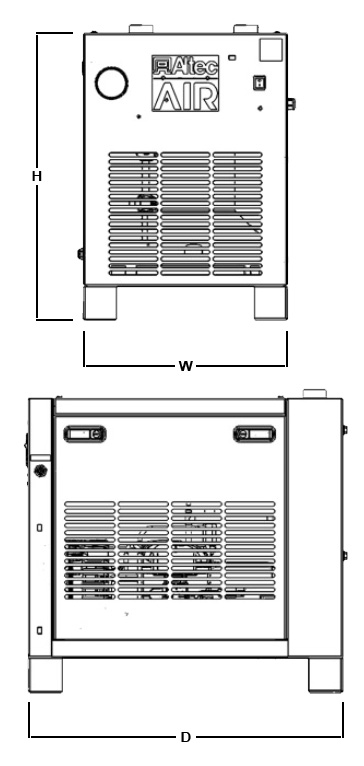

| Dimensions: | ||||

|---|---|---|---|---|

| Weight* (lbs) |

Height (in) |

Width (in) |

Depth (in) |

|

| RAD-0025A | 98 | 26 | 17 | 19 |

| RAD-0040A | 105 | |||

| RAD-0055A | 108 | |||

| RAD-0075A | 160 | 26 | 18 | 28 |

| RAD-0100A | 172 | |||

| RAD-0150A | 215-233 | 30 | 22 | 34 |

| RAD-0200A | 245 | |||

| RAD-0250A | 285-305 | 38 | 24 | 35 |

| RAD-0300A | 295-305 | |||

| RAD-0400A | 500-546 | 46 | 29 | 43 |

| RAD-0500A | 526-546 | |||

| RAD-0600A | 526-546 | |||

| RAD-0750A | 580-600 | 56 | 34 | 53 |

| RAD-1000A | 875-895 | |||

| RAD-1250A | 875-895 | |||

| RAD-1500A | 1400 | 70 | 40 | 56 |

| RAD-2000A | 1595 | |||

* Weights may vary based on Voltage Option required.

| **Multiplier Tables (Sizing Dryers for Variable Conditions): | ||||||||

|---|---|---|---|---|---|---|---|---|

| Corrected Inlet Flow Capacity = | ||||||||

| INLET Flow (above) | x | Inlet Pressure Correction Factor (A) |

x | Inlet Temp Correction Factor (B) |

x | Ambient Temp Correction Factor (C) |

||

| Actual Pressure (PSIG) | 50 | 80 | 100 | 125 | 150 | 175 | 200 |

| Correction Factor (A) | 0.82 | 0.95 | 1.00 | 1.05 | 1.09 | 1.12 | 1.15 |

| Inlet Temp (°F) | 80 | 90 | 100 | 110 | 120 | 140 |

| Correction Factor (B) | 1.72 | 1.28 | 1.00 | 0.80 | 0.66 | 0.45 |

| Ambient Temp (°F) | 80 | 90 | 100 | 110 | 120 |

| Correction Factor (C) | 1.08 | 1.06 | 1.00 | 0.90 | 0.76 |

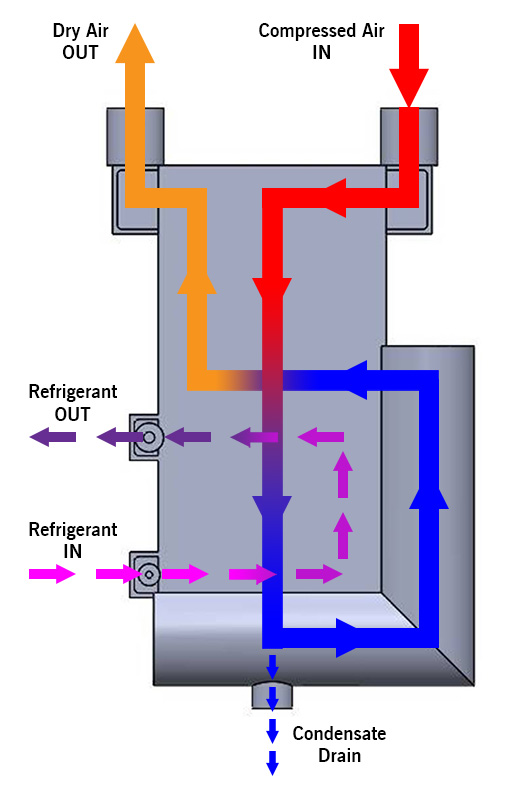

Refrigeration Air Drying Process

Altec AIR Refrigerated Air Dryers use refrigeration cooling to condense moisture and remove it from a compressed air system.

- Warm saturated air enters a pre-cooler/re-heater heat exchanger at the dryer inlet and is pre-cooled by outgoing cold air.

- The pre-cooled air then enters the air to refrigerant heat exchanger and is cooled to its lowest point.

- As the air is cooled, the moisture it contains changes from a vapor to a liquid and is removed by a stainless-steel mesh separator and discharged from the dryer through an automatic drain valve.

- The cold air is then re-heated by incoming warm air as it passes back through the pre-cooler/re-heater.

- The resulting warm air that exits the dryer is clean, dry and ready for use by a compressed air system.

This tool will help you size the perfect RAD Series Non-Cycling Refrigerated Air Dryer for your Compressor Output and Environmental Conditions. Simply enter the data & conditions and you'll be presented with the Part Number for the RAD Series Air Dryer that will work optimally for those conditions. We will also provide Part Numbers for the Filter Kits that were created to match that RAD Series Air Dryer perfectly.

Please use the latest version of Chrome, Firefox or Safari.

Internet Explorer not currently supported.

Required *

Please use the latest version of Chrome, Firefox or Safari.

Internet Explorer not currently supported.